280 FOOD GRADE HTC

280 Food Grade HTC is an anti-wear, food grade oil that is specially formulate for use in the lubrication of food, feed and pharmaceutical processing and packaging equipment, especially those pieces of equipment that are subjected to high loads and high moisture conditions.

280 Food Grade HTC meets the requirements for a USDA H-1 quality lubricant and the requirements of the United States Code of Federal Regulations 21CFR 178.3570, 178.3620(b), and 573.680 of the United States Food and Drug Administration’s Regulations.

280 Food Grade HTC can be used in the lubrication of all types of compressors, hydraulic, vacuum pump, pump, airline, chain, bearing, and general oiling applications where there is a chance of incidental contact with food, foodstuffs, drinking water, potable water, or ground water may occur. Typically, these applications can be found in the following industries:

|

Meat & Poultry Processing Plants

|

Egg Processing Plants

|

|

Fish & Seafood Processing Plants

|

Breweries & Wineries

|

|

Soft Drinks & Bottling Plants

|

Vegetable & Fruit Processors

|

|

Cheese & Cheese Product Producers

|

Bakeries

|

|

Snack Food Manufacturers

|

Pasta Manufacturers

|

|

Pet Food & Animal Feed Producers

|

Oil Mils & Seed Cake Processors

|

|

Pharmaceutical & Drug Manufacturers

|

Cosmetic Manufacturers

|

|

Food & Beverage Container Manufacturers

|

Paper & Paper Board Manufacturers

|

|

Water Well Drillers

|

Drinking & Portable Water Treatment

|

280 Food Grade HTC is blended from the finest quality, highly refined, severely hydro-finished, purified, non-toxic, non-staining 100% paraffin base technical white and U.S.P. grade white oils available. Combined with these paraffin base technical white oils is a specialized non-toxic food grade approved additive package, which provides the 280 Food Grade HTC with the following performance characteristics:

1. Excellent lubricity and film strength

2. Enhanced oxidative stability

3. Excellent resistance to thermal degradation

4. A high viscosity index

5. Excellent hydrolytic stability and resistance to emulsification

6. Excellent resistance to acidic compounds

7. Exceptional anti-wear and load carrying capabilities

8. Excellent rust and corrosion inhibition

9. Excellent anti-foam and air release properties

10. Protection against rancidity and build up due to bacterial and fungal

growth

11. Longer service life and less deposit formation

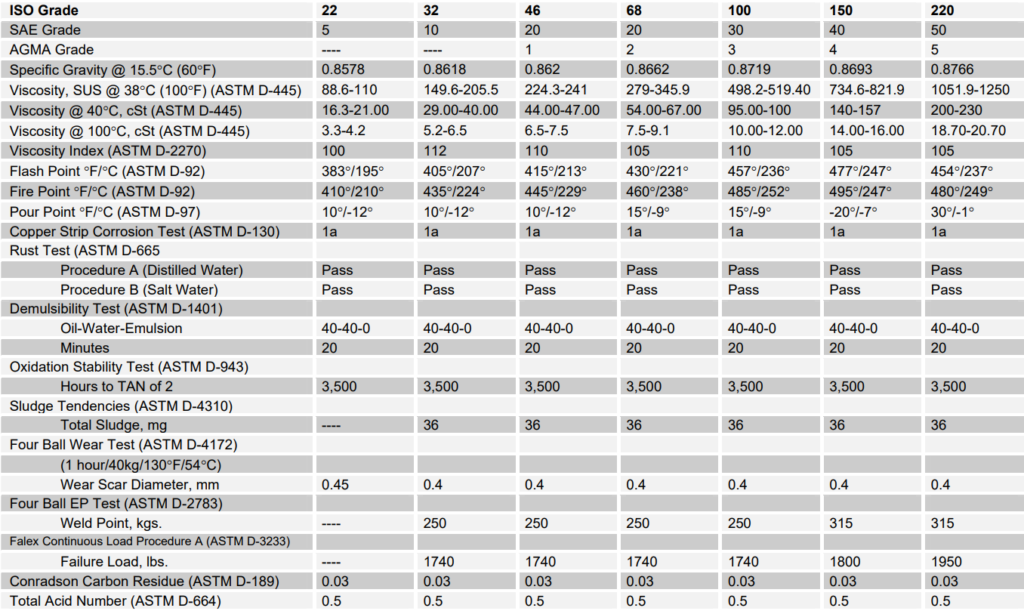

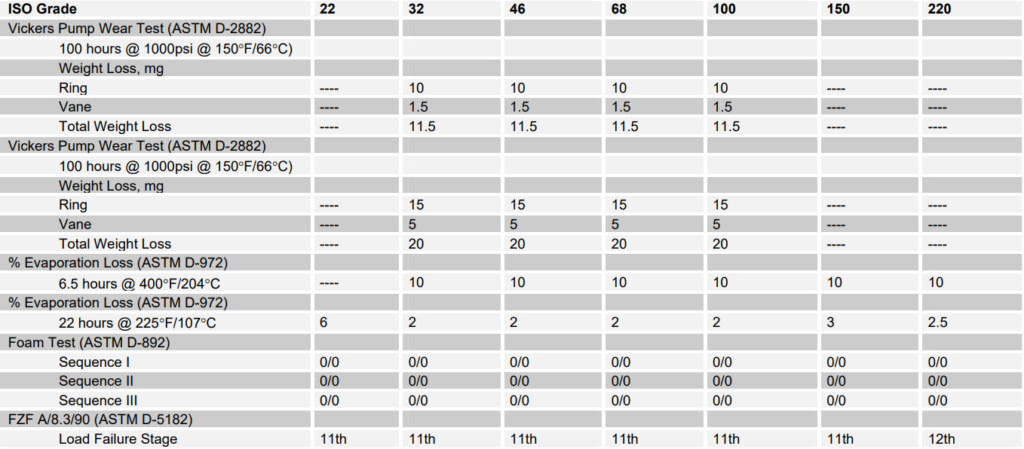

TYPICAL PROPERTIES: