295 CABLE & WIRE ROPE LUBE

M-295 Cable & Wire Rope Lubricant is a heavy duty extreme pressure lubricant that is specially formulated to provide extended service life over a wide range of temperatures to all types of wire ropes common to the mining, construction and marine industries.

Packaging: 18 KG

M-295 has long lasting protection because of its ultra tackiness, heavy duty, tenacious and durability of coating, and yet it is an Asphalt-free lubricant. And is compounded from a blend of high viscosity index paraffin base oils, synthetic base oils and penetrating oils. These oils were selected for their strong adhesive and film forming characteristics, exceptional wetting and fast penetrating abilities, and exceptional chemical stability. Also the high viscosity index of these oils assures that it will not harden at low ambient temperatures or become thin and run at high ambient temperatures.

Blended into these oils is a special additive package which allows M-295 Cable & Wire Rope Lubricant to provide:

1. Excellent anti-wear and extreme pressure protection to reduce metal to metal contact between the wires during operation.

2. Rust and corrosion protection within the core, adjacent wires and exterior surfaces.

Further blended into M-295 is a combination of molybdenum disulfide and various solid lubricants. This combination of molybdenum disulfide and various lubricants not only fortifies the film strength, but also improves the anti-wear and extreme pressure characteristics of Wire Rope Lubricant beyond those of conventional or asphaltic wire rope lubricants. By fortifying film strength and improving the anti-wear and extreme pressure characteristics, friction and wear is significantly reduced between the rope strands and to the sheaves and drums over which the ropes are drawn.

The penetrating oils present in Wire Rope Lubricant allow the combination of molybdenum disulfide and various solid lubricants to penetrate the inner wire rope core. This penetration the inner wire rope core. This penetration of the wire rope core provides not only increased wear protection but also allows for the lubrication of these vital parts of the wire rope.

M-295 contains a combustible non-chlorinated solvent that optimizes the viscosity of the product as it evaporates. The evaporation of this solvent allows Wire Rope Lubricant to rapidly form a weather resistant protective coating while still allowing for rapid penetration of the wire rope.

M-295 Cable & Wire Rope Lubricant provides the following performance advantages:

1. Significant reduction of fretting corrosion.

2. Resistance to water wash out.

3. Resistance to corrosion by acid, alkalines or salt water.

4. Rapid displacement of moisture.

5. Formation of a tough pliable film that is strongly resistant to chipping and peeling in cold weather and resistant to drying out with heat and age.

6. The formation of a non-tacky surface that resists adhering of dirt and abrasives.

7. Adhesiveness to prevent throw-off due to vibration or sudden changes of direction.

Application:

Recommended to Use on Arduous rope such as ; drag-line hoist and drag ropes and underground mine drift ropes, shafts winding rope, flexible coupling chains, and partly enclosed gears. Also on sliding surfaces of drag lines and shovels, open gears of mine hoists, ball mills, rubber mixers, cement mills, coke ovens, construction equipment and other application where adhesive grease is required. It can be applied manually or through the use of an automatic spray system.

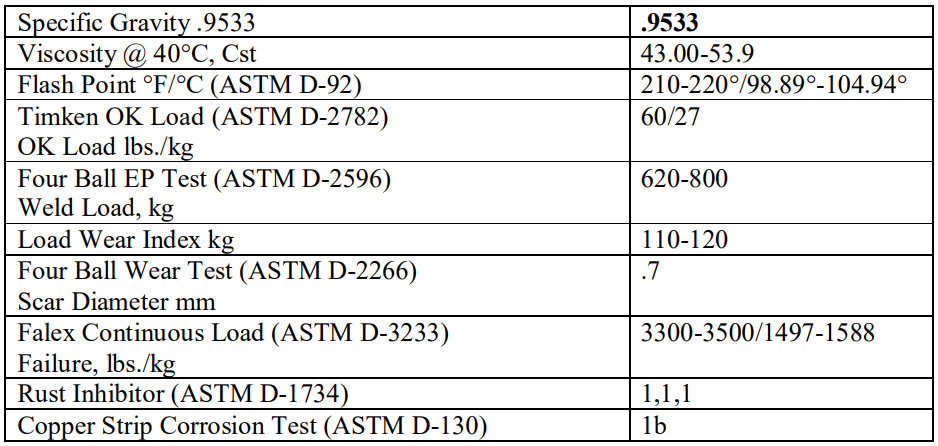

TYPICAL SPECIFICATIONS: