286C ANTI SIEZE COPPER COMPOUND

Hi-Temp Anti Seize Compound With Copper is a high temperature synthetic silica thickened anti-wear, extreme pressure grease that is specially formulated for those industrial bearing applications, where extremely high temperature are encountered up to 1193 °C.

Packaging: 18 KG

Anti Sieze Compound With Copper is compounded from a blend of polyethylene glycol synthetic base fluids and a silica based thickener system. Further blended into these polyethylene glycol synthetic base fluids and the silica based thickener system is a

proprietary high temperature antiwear extreme pressure additive and a combination of molybdenum disulfide, graphite and copper flake.

As high temperatures occur the Hi-Temp Grease With Copper will gradually soften in consistency without any drippage of the synthetic base fluids, in order to carry and spread the molybdenum disulfide, graphite and copper flake into the bearing clearances and onto the bearings surfaces. As the temperatures continues to become elevated the synthetic base fluids begin to volatilize cleanly without leaving any residues, varnishes, gums or carbon deposits on the bearing surfaces. Once the synthetic base fluids have volatilized off a solid lubricant film consisting of the high temperature anti-wear extreme pressure additive and the combination of molybdenum disulfide, graphite and copper flake is left behind to lubricate at very high temperatures.

Anti Seize With Copper’s extreme pressure additive, molybdenum disulfide, graphite and copper flake has a natural affinity for metal surfaces. This natural affinity for metal surfaces allows this solid lubricant combination to plate themselves to these surfaces in order to form a long lasting solid lubricant film which not only withstands high temperatures, but also will withstand pressures in excess of 500,000 psi. This long lasting solid lubricant film provides the metal surfaces of the bearings the superior protection they need especially during periods of high shock loading, extreme pressure and vibration.

The solid lubricant film also helps to reduce friction. This reduction in friction results in reduced wear which in turn leads to increased bearing life, energy savings, less downtime and extended lubrication cycles.

Anti Seize With Copper also has excellent rust and oxidation inhibiting characteristics, very good water resistance and good mechanical and shear stability and very good adhesive properties. Further, the Hi-Temp Grease With Copper adhesive properties prevent the Hi-Temp Grease With Copper from washing out, pounding out, splattering or being squeezed

out even under the heaviest loads and vibrations.

USES:

- Kiln Car Wheels.

- Conveyors in Ovens.

- Coke Oven Door Latches.

- Oven Damper Control Bearings.

- Roller Chains.

- Larry Car Journals.

- Charging Cars.

- Furnace Table Bearings.

- Soaking Door Pits.

- Tenter Frames.

- Pallet Wheels.

- Dollies and Dogs of Hot Beds.

- Stack Valves.

- Ignot Buggy Tilt Bearings.

- Cement Mill Clinker Dryers.

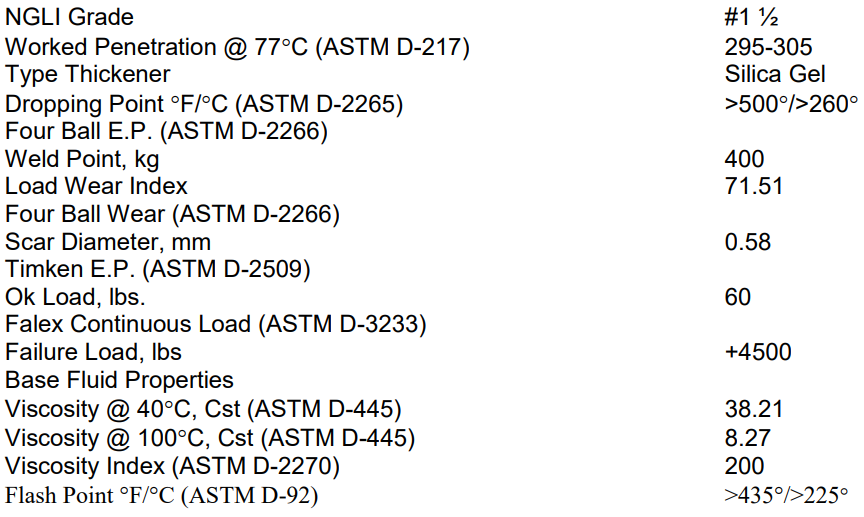

TYPICAL SPECIFICATIONS: